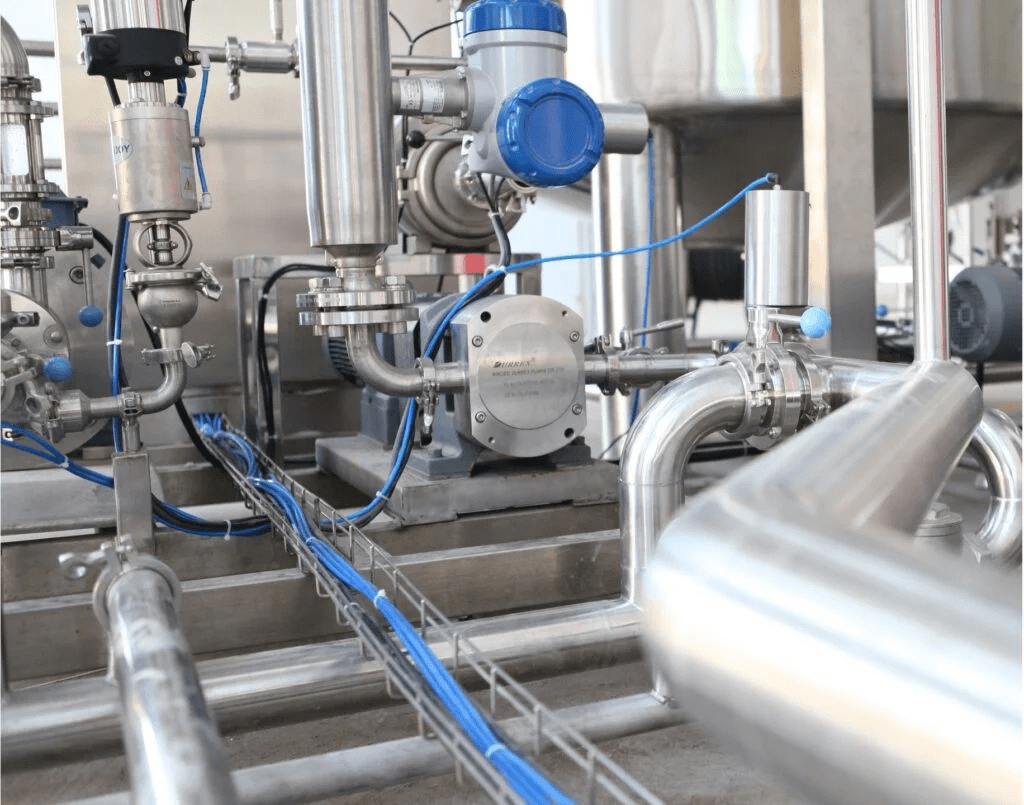

Liquid flow meters are integral components in various industrial processes, providing crucial measurements that influence operational efficiency and product quality.

Accurate flow meter readings are essential for ensuring processes run smoothly and consistently.

In this article, we will delve into the fascinating world of liquid flow meter technology, explore the significance of accuracy in industrial applications, and dissect the factors that can affect flow meter accuracy and performance.

Importance of Liquid Flow Meter Accuracy

Accurate flow rate measurements are paramount in industries where precise control of fluid flow rates is essential. From chemical manufacturing to oil and gas production, accurate flow data impacts product quality, regulatory compliance, and cost control.

Inaccurate measurements can lead to costly errors, process inefficiencies, and even safety hazards. As such, industries rely on advanced flow meter technology to achieve the highest level of accuracy possible.

Types of Liquid Flow Meters

Understanding the nuances of these flow meter specifications is imperative for industries seeking optimal accuracy and efficiency in their operations.

Vortex Flow Meters

Vortex flow meters operate on the principle of the Von Kármán effect, where fluid flow creates alternating vortices that are proportional to the flow rate.

These meters are suitable for a wide range of applications, including steam flow measurement, where their robust construction and high accuracy shine.

Coriolis Flow Meters

Coriolis flow meters rely on the Coriolis effect, where a vibrating tube experiences a phase shift due to fluid flow.

These meters excel in measuring mass flow and are widely used in industries such as pharmaceuticals and food production, where precise control of ingredient quantities is critical.

Electromagnetic Flow Meters

Electromagnetic meters employ Faraday’s law of electromagnetic induction to measure flow velocity.

They are ideal for applications involving conductive fluids and are known for their accuracy and reliability. These meters find extensive use in water treatment and wastewater management.

Turbine Flow Meters

Turbine flow meters consist of a rotating turbine placed in the fluid path. The flow rate is determined by measuring the speed of minimum and maximum flow made through the turbine.

These meters are suitable for clean, low-viscosity liquids and are frequently used in the petrochemical industry.

Clamp-On Ultrasonic Flow Meters

A clamp-on ultrasonic flow meter is a cutting-edge instrument that utilises ultrasonic waves; it operates externally without direct contact with the fluid. By measuring sound wave travel times, it calculates velocity and flow rate accurately.

This flowmeter is versatile, finding applications in water management, oil and gas, and chemical processing. Its non-intrusive nature and precise measurements make it indispensable across industries.

Factors Influencing Flow Meter Accuracy

Flow Profile and Disturbances

The flow profile, or how the fluid moves within the pipe, can significantly impact measurement accuracy.

Disturbances in the flow, such as turbulent eddies or swirls, can introduce errors. Proper pipe design and flow straighteners help mitigate these effects.

Fluid Viscosity

Viscosity, the resistance of a fluid to flow affects the accuracy of flow meters. Higher viscosity fluids may require corrections to ensure accurate measurements of maximum flows. Flow meters with viscosity compensation mechanisms can provide more precise readings.

Pressure and Temperature

Pressure and temperature variations can alter fluid properties and affect flow meter accuracy. Some meters offer temperature compensation to maintain accuracy across a wide temperature range.

Accuracy Requirements

Each industry has specific accuracy requirements that flow meters must meet. For instance, pharmaceutical manufacturing demands extremely high accuracy to ensure product quality, while other applications may tolerate lower levels of precision.

Repeatability and Stability

Repeatability, the ability to reproduce measurements consistently under the same conditions, and long-term stability are critical for maintaining measurement accuracy over time. Regular calibration and maintenance are essential to ensure stability.

Installation and Environmental Factors

Proper installation techniques, such as ensuring the meter is correctly aligned and adequately supported, are crucial for accuracy. Environmental and other factors, such as vibration or electrical interference, can also influence meter performance.

Full-Scale Accuracy vs. Low Flow Rates

Navigating the intricacies of a flow meter’s accuracy involves a critical consideration: the balance between full-scale accuracy and low flow rates.

In the world of flow meters, some devices shine when handling high flow rates, but the real challenge lies in accurately measuring those subtle, low flow rates that are equally vital in many industrial processes.

Industries and applications vary significantly, from large-scale manufacturing processes to precise pharmaceutical dosing. Ensuring that your chosen flow meter maintains its accuracy, whether you’re dealing with a torrential flow or a gentle trickle, is paramount.

Achieving this delicate equilibrium is a testament to a flow meter’s quality and design. Flow meters must be meticulously calibrated and engineered to meet the demands of diverse operational conditions.

Whether you’re working with high-flow industrial applications or carefully measured low-flow rates, a dependable flow meter should provide the accuracy and reliability necessary for optimal performance.

Achieving High Accuracy in Liquid Flow Measurement

In the realm of liquid flow meter measurement, precision and absolute accuracy are paramount, and advancements in flow meter technology are playing a pivotal role in raising the bar for accuracy.

The continuous evolution of these devices has ushered in an era of unparalleled precision, bolstered by innovative features like digital signal processing and the integration of cutting-edge sensor materials.

Digital Signal Processing

Digital signal processing (DSP) has revolutionised the way flow data is collected and processed. By employing sophisticated algorithms, DSP can filter out noise, rectify signal distortions, and enhance the overall accuracy of flow measurements.

This technology not only minimises errors but also ensures stability over time, making it a game-changer for industries that demand consistently precise measurements.

Understanding Measurement Data

Understanding the data generated by flow meters is just as crucial as the technology itself. A clear comprehension of measurement data, coupled with the ability to interpret it accurately, is essential for maximising the meter accuracy.

By harnessing the power of these technological advancements and developing a deep understanding of measurement data, industries can achieve the high level of accuracy required for critical liquid flow measurement applications.

In Summary

The accuracy of liquid flow meters plays a pivotal role in numerous industrial applications. Precise flow measurements are essential for maintaining process efficiency, ensuring product quality, and adhering to regulatory standards.

Selecting the right flow meter for your specific application and partnering with a trusted supplier, such as AMS IC, can significantly impact the success of your operations.

Contact AMS For Quality Flow Meters

Explore our extensive range of high-quality liquid flow meters designed to meet the stringent demands of various industries.

Whether you require accurate measurements for chemical processes, water management, or oil and gas production, AMS IC has the expertise and products to meet your needs. Contact us today to discuss your needs and discover how our flow meters can enhance your operations.