9 Reasons to use a digital flow meter

Traditional VA meters have some great aspects; they are simplistic in design, relatively low cost, low maintenance and are easy to install. But also have some drawbacks. Traditinial purge meters are accurate for a certain medium at a given temperature and pressure.

A digital alternative to the traditional VA meters is a digital flow meter.

Read more about the differences and why a digital flow meter could be interesting for you to use instead.

What is a VA flow meter or purge meter?

VA meters are also called purge meters. Over the years, different types of VA flow meters have been developed, usually in response to some specific need. VA flow meters consist of a cone, typically made of glass or plastic, float made either of anodised aluminum or a ceramic, scale, and a process connection. Operating under the variable area flow principle, VA flow meters or Purge meters use a simple design in which a float rises inside a conically shaped glass tube as the flow increases and its position on the scale gives the flow rate.

How does a VA meter/purge meter work?

While the meters are still relatively simplistic in design, relatively low cost, low maintenance and ease of installation they are widely used in many kinds of applications. Despite these facts, the traditional VA meter has a number of drawbacks.

For instance, graduations on a given purge meter will only be accurate for a given substance at a given temperature and pressure. Either way, due to the direct flow indication, the resolution is relatively poor anyway. Especially when they are built into a machine, reading might be hard. Moreover, the float must be read through the flowing medium, so you can imagine that some fluids may obscure the reading.

9 Reasons why to use a digital flow meter

As for the current century, Bronkhorst developed the MASS-VIEW flow meter series which is the digital high-tech alternative to these traditional VA meters. Thanks to today’s digital possibilities, many other advantages arises for many industrial processes and chemical plants.

- The MASS-VIEW digital flow meter series operate on the principle of direct thermal mass flow measurement (no by-pass); rather than measuring the volume flow it measures the actual mass flow, without the need of temperature and pressure correction.

- The digital OLED display provides you an easy direct or relative reading of the actual flow. Herewith parallax errors are excluded.

- With this digital flow meter, you can obtain the accumulated flow easily. This availability of data gives insight in costs, leading to data driven decision making power.

- A digital flow meter can be mounted in any position. The VA meter needs to be mounted in a vertical position.

- The flow path is made of sustainable aluminum rather than plastic or glass which is fragile.

- The digital instruments are standard equipped with 0-5V, RS-232 and Modbus-RTU output signals. The VA meters usually do not have any output signal available at all.

- The digital flow meter has 2 built-in relays which indicate an alarm situation. Herewith, external devices can be controlled.

- A MASS-VIEW flow meter has multiple pre-installed gases on board as opposed to traditional VA meters, which are produced for one particular fluid only.

- Digital instruments have a rangeability of 1:100 and 4 pre-installed ranges, as opposed to VA meters usually have a rangeability of 1:10 and one single full scale range only.

Achieve a stable flow using a valve

A VA meter, whether it is a conventional or a digital one, can be equipped with a built-in needle valve. This needle valve enables the user to regulate the flow rate by means of a restriction inside the flow channel. As long as the inlet pressure is stable, the subsequent flow will be stable too. On the other hand, once pressure conditions are susceptible to change, the flow rate will become equally unstable. If this is not desirable, you’ll have to compensate these pressure fluctuations.

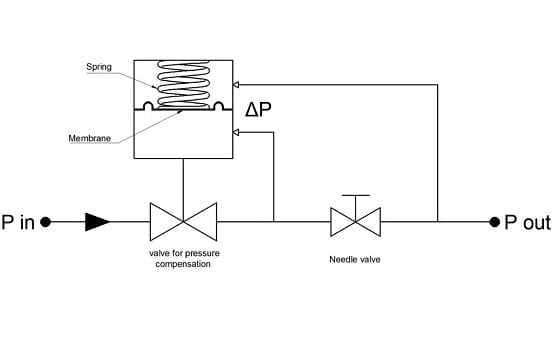

This effect can be eliminated by using a manual control valve like the FLOW-CONTROL series which keeps the pressure drop across the needle valve (delta-P) constant. This is accomplished by a second (normally open) valve, though it is operated by a membrane this time. The operating principle is based on a balance that forms between the pre-pressure, back-pressure and the spring force on the membrane. A change in the pressure conditions leads to a change of the equilibrium and thus a change in the valve position as well (as shown in the picture below).

Although Bronkhorsts’ pressure compensation technology is suitable for either gases and liquids, the nice thing about this is that both technologies, the digital VA meters and pressure compensation, lend themselves well to being built together. However, in that case it is applicable for gases only.

Reprinted from Bronkhorst

For further information contact Dave Grey dave.g@ams-ic.com.au