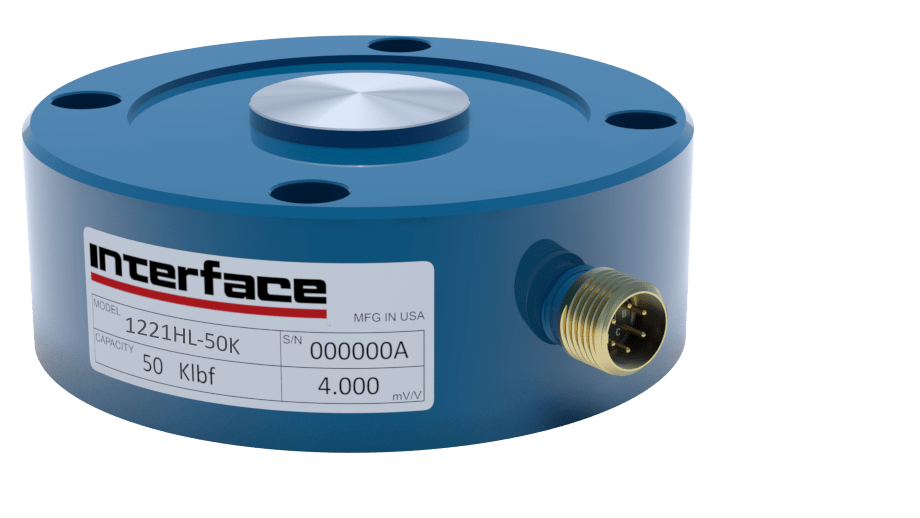

Load cells are used to test and confirm the design of hardware, components, and fixtures used across industries and by consumers. From the structural integrity of an airplane to the sensitivity of a smartphone touchscreen, there is a load cell available to measure force. In fact, here at Interface we have over tens of thousands of products used in force measurement, for all types of different applications.

How do engineers and product designers go about choosing the right load cell for a specific application or testing project?

Have no fear, here is a short guide on choosing the load cell that is right for you. This blog will cover the basic questions to answer when selecting a product, as well the most important factors affecting load cell choice.

The basic questions you need to consider when selecting a load cell include:

- What are the expected loads? What is the minimum and maximum load you’ll be measuring?

- Is there any potential for higher peak loads than what you intend to measure? What are these expected peak forces?

- Is it tension, compression, or both?

- Will there be any off-axis loads? If so, what is their geometry? Do you want to measure them too?

- Will it be a static, dynamic or fatigue measurement?

- What is the environment in which you’ll be conducting your test? Will the load cell need to be sealed?

- How accurate do your measurements need to be? Do they need to be at the highest accuracy of ±0.02-0.05% or within ±0.5-1%?

- What additional features, accessories and instrumentation does your application require to complete a test?

- Do you need standard electrical connectors or customized options? What about additional bridges or amplifiers?

- How are you planning to collect and analyze the data output from the load cell?

Next, these are the most important factors affecting accuracy, which will have a heavy influence over the load cell you choose. It’s important to understand how your application and the load cell will be affected by each of the factors, which include:

- Mechanical – Dimensions and Mounting

- Electrical – Output and Excitation

- Environmental – Temperature and Moisture

One of the most important factors in choosing the right load cell is understanding how it will be mounted for testing or as a component within a design. There are a wide variety of mounting types including threaded connections, inline, through hole or even adhesive. Understanding the mounting type that suits your application is critical to getting the correct data because a poorly mounted load cell will distort the results and can damage the load cell.

The mounting process also requires you to understand which direction the load is coming from, in addition to any extraneous loads that may be present. The load cell mating surface is also an important factor. For example, when using our LowProfile® load cells without a pre-installed base, the best practice is to ensure that the mating surface is clean and flat to within a 0.0002-inch total indicator reading and is of suitable material, thickness, and hardness (Rc 30 or higher). Also make sure that bolts are torqued to the recommended level.

If you’re conducting a fatigue measurement, it’s also important to address the frequency and magnitude of load cycles with your load cell provider. Factors to address include single mode versus reverse cycles, deflection versus output resolution, and material types. Interface offers a wide variety of fatigue-rated load cells that are perfect for these types of applications.

Another consideration in choosing the right load cell is the electrical signal. Load cells work by converting force into an electrical signal. Therefore, it’s important to understand the electrical output type necessary for your application, which could include millivolt, voltage, current or digital output. You can find the excitation voltage data on our website for each of our load cells. Additional considerations include noise immunity, cable length and proper grounding.

The environment is also a critical factor in ensuring accurate performance of your load cell. Interface provides load cells in a variety of material types including aluminum, steel, and stainless steel. Each material has a variety of properties that make them more suitable for different environments.

How AMS Instrumentation & Calibration Ensures Accurate Measurement

At AMS Instrumentation & Calibration, we understand that every industry has unique needs when it comes to loadcell measurement. We offer a range of high-quality load cells, torque transducers, multi-axis sensors, and related instrumentation.

For more information about how we can support your business, or to schedule a consultation, contact us today. Visit our Contact Us page to get started and let AMS help you achieve the accuracy your operations demand.