Accurate calibration plays a crucial role in ensuring precise and reliable measurements across various industries. At the heart of this process lies the calibration test bench, a powerful tool that enables technicians to achieve accuracy and repeatability.

In this article, we will explore the features and functionalities of calibration test benches, discuss their role in maintenance, and highlight the benefits they offer in enhancing calibration processes.

Importance of Accurate Calibration in Industrial Sectors

Accurate calibration is essential in industries such as manufacturing, engineering, and scientific research, where precise measurements are critical for quality control, compliance, and safety. Calibration test benches play a vital role in ensuring that instruments and devices provide accurate readings, facilitating optimal performance and maintaining operational efficiency.

Understanding Calibration Test Benches

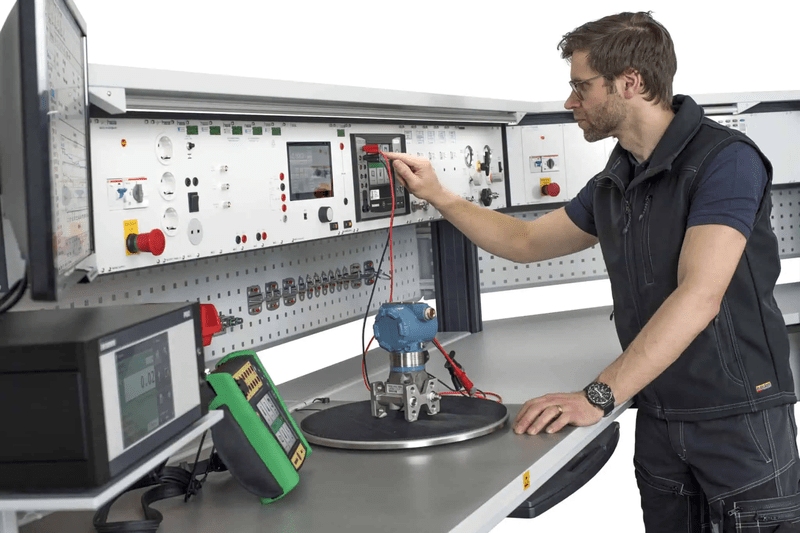

A calibration bench is a sophisticated piece of equipment designed to assist in the calibration, verification and adjustment of instruments and devices. These benches provide a controlled and stable environment that replicates real-world conditions, allowing technicians to assess the accuracy and performance of various instruments.

Their primary purpose is to establish precise temperature and pressure calibration standards and maintain instrument integrity.

Features and Functionalities of Calibration Benches

Calibration test benches offer a wide array of features and functionalities to support accurate calibration processes:

- Versatility: Test benches cater to a diverse range of instruments and devices, including electrical, temperature, pressure, and flow measuring devices.

- Customisation: Many calibration test benches can be customised to meet specific calibration needs, allowing technicians to configure the bench according to the required parameters and measurement ranges.

- Calibration Procedures: Test benches offer predefined calibration procedures and standards in a controlled environment, ensuring technicians follow consistent protocols for accurate and repeatable measurements.

- Traceability and Documentation: Calibration test bench procedures enable traceability by providing proper documentation of calibration procedures, and ensuring compliance with regulatory and quality assurance requirements.

- Advanced Measurement Technologies: Many test benches incorporate advanced measurement technologies to enhance accuracy and precision, enabling technicians to calibrate instruments to high standards.

Benefits of Using Calibrated Test Benches

Calibrated test benches offer several advantages in the calibration and testing process:

- Reliable and Repeatable Results: Calibrated test benches provide confidence in the accuracy and reliability of calibration results, ensuring consistent performance of instruments and devices.

- Compliance with Accreditation Requirements: Accredited laboratories must meet stringent quality standards. Calibrated test benches assist in meeting accreditation requirements, ensuring traceability and reliable calibration results.

- Meeting Customer Requirements and Industry Standards: Different industries have specific calibration needs and standards. Calibrated test benches enable laboratories to meet customer requirements and comply with industry-specific regulations.

- Increased Efficiency and Productivity: Well-calibrated test benches streamline calibration processes, reducing errors, and minimising downtime. This leads to improved efficiency and productivity in calibration work.

- Accurate Temperature and Pressure Calibration: Calibration test benches enable precise calibration of temperature and pressure instruments, ensuring accurate readings and optimal performance.

Calibration Test Bench Procedures and Standards

Calibration procedures and industry standards are crucial components of the calibration process, ensuring the accuracy, reliability, and traceability of measurements.

These procedures provide technicians with step-by-step instructions to follow, ensuring consistency and uniformity across calibration processes.

One significant aspect of calibration procedures is traceability. Traceability establishes a clear calibration chain, linking the measurements to internationally recognised standards.

This enables the measurement results to be compared and verified against a known reference, enhancing confidence in the accuracy of the calibration.

Industry standards, such as ISO/IEC 17025 and ANSI/NCSL Z540, provide comprehensive guidelines for competence, technical requirements, and quality systems in calibration laboratories.

These standards ensure that calibration processes are conducted with the highest level of proficiency and conformity of technical specifications to recognised practices.

Moreover, quality control and assurance practices are integral to calibration procedures and standards. These practices aim to ensure complete adherence to established procedures, identify and address any deviations or uncertainties, and continually optimise calibration work.

The Role of Calibration Benches in Maintenance

Maintenance activities rely on accurate calibration, and calibration test benches play a crucial role in this process:

- Performing Routine Calibration: Regular calibration ensures that instruments and devices maintain accuracy and reliability over time. Calibration test benches enable technicians to perform routine calibration, detecting any deviations and allowing for adjustments or repairs.

- Conducting Temperature and Pressure Calibration: Calibration test benches facilitate calibration for various parameters, including temperature and pressure. This ensures instruments operate within specified ranges and perform accurately.

- Maintaining Calibration Equipment: Regular maintenance of calibration test benches ensures their proper functionality, contributing to accurate calibration and reliable measurement results.

Choosing the Right Calibration Bench

Selecting the appropriate calibration test bench is vital to achieving accurate and reliable calibration results:

- Evaluate the workload and types of instruments requiring calibration

- Assess the calibration parameters and instruments to select a suitable test bench

- Consider the calibration range and accuracy requirements for precise results

- Take into account the physical characteristics of the test bench, such as size, weight, and portability

- Ensure compatibility with industry standards and traceability requirements

- Evaluate the availability of accessories and accompanying products for enhanced functionality

- Consider the overall value and cost-effectiveness of the test bench

- Select a test bench that aligns with specific calibration needs and budget constraints

- Optimise calibration work by choosing the appropriate test bench for efficient and accurate measurements

Contact Us For Calibration Bench Solutions

Calibration test benches are indispensable tools for maintaining accuracy and precision in calibration processes. They offer a comprehensive range of features and functionalities to support reliable measurements and compliance with industry standards.

Explore our range of calibration equipment to find the ideal calibration test bench for your specific needs. Visit our product page for more information, and feel free to contact us for further assistance.

Elevate your calibration processes to new levels of accuracy and reliability with our quality calibration test benches.